Epoxy Floor Coating

Epoxy Floor COating

Durable, Stylish & Built to Last

Tired of boring concrete?

We turn dull floors into stunning surfaces that look like art and perform.

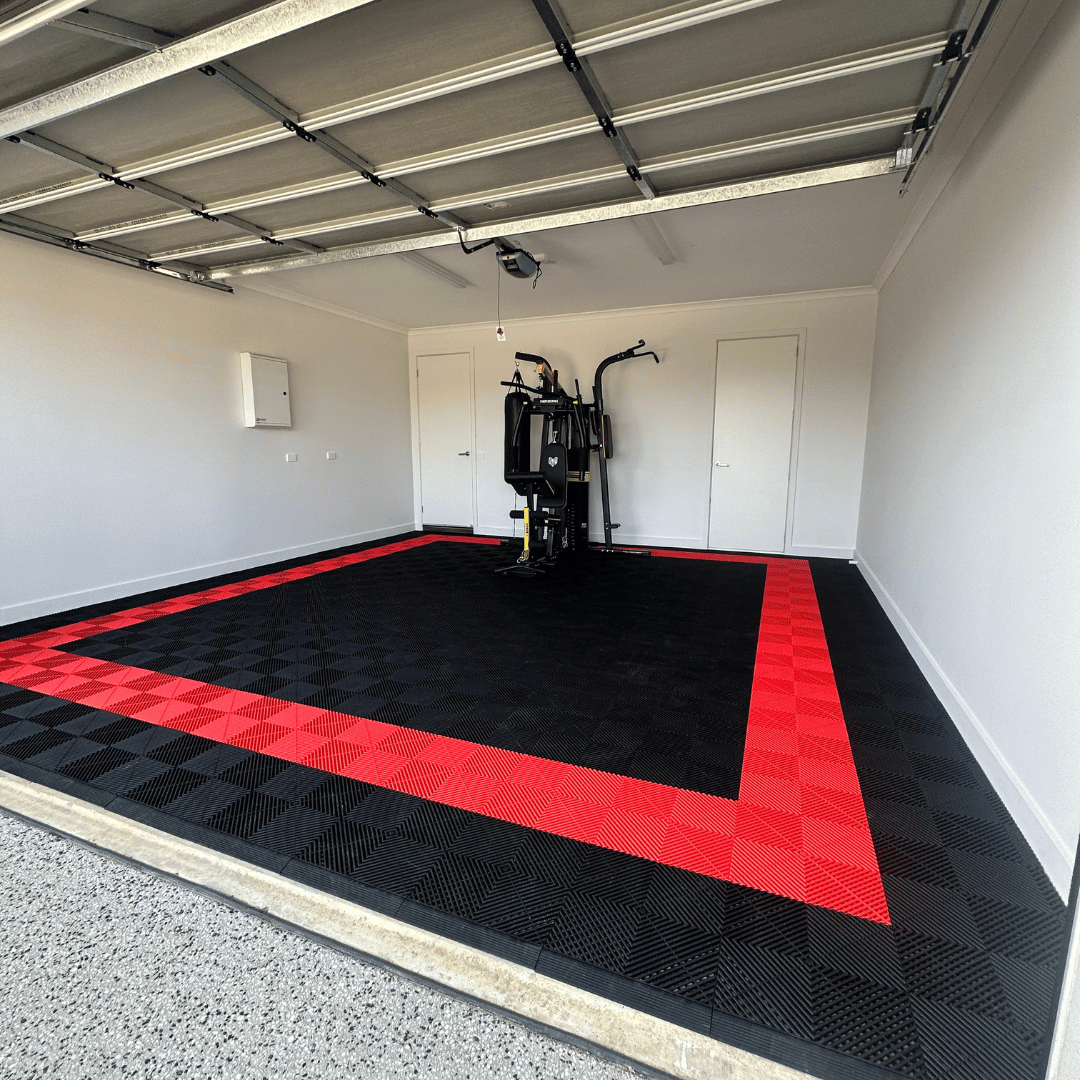

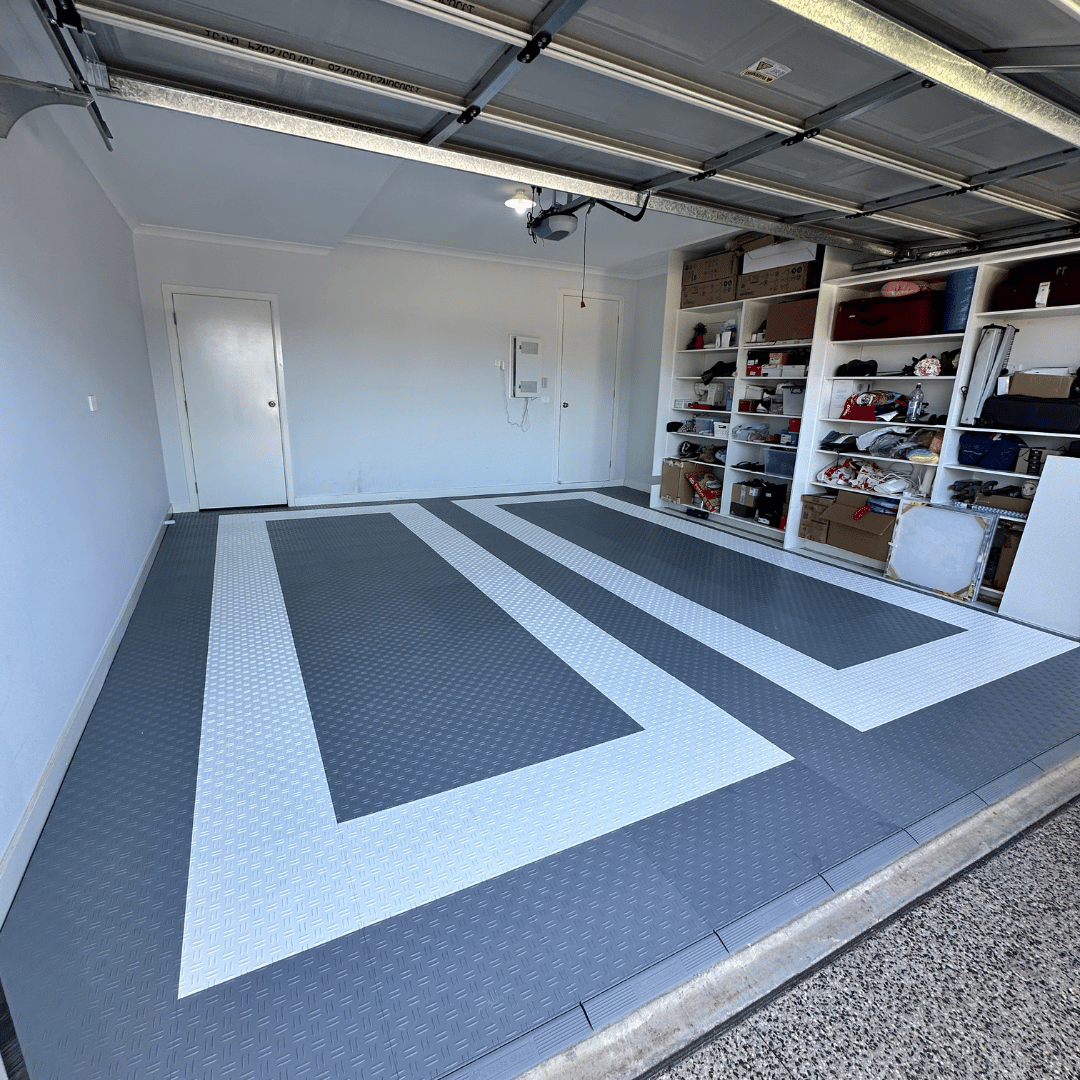

Give your garage floor a complete transformation with epoxy floor coating a sleek, high-gloss solution that’s built to last. At Dwell Garage Masters, we specialise in delivering professional-grade epoxy flooring for garages in Werribee and across Melbourne’s western suburbs.

Our epoxy coatings are more than just good-looking they offer long-lasting protection against oil stains, chemicals, abrasions and everyday wear. Whether you want a clean, polished finish or a custom flake blend, we customise the result to your style and needs.

5 Star

Google Rating

500+

Epoxy Floor coating work done

100%

Costumer Satisfaction

No

Call Out Fee

Why you should choose Epoxy Floor Coating?

Stain & Chemical Resistance

Heavy-Duty Durability

Slip Resistance

Low Maintenance

4-Step Epoxy Coating Process

Surface Prep & Grinding

We mechanically grind your existing floor to remove contaminants and open the surface for strong epoxy adhesion

Crack & Damage Repair

We fill in cracks, holes, and surface imperfections for a smooth, level base

Epoxy Application

We apply high-quality epoxy with optional flake/chip finish or metallic coat, depending on your preference

Topcoat Seal & Curing

A tough polyurethane topcoat locks in the finish for long-lasting shine and durability

Typical install time: 1–2 days (including cure time)

Epoxy Floor Coating

The best choice

Epoxy floor coatings are a popular choice for both commercial and residential spaces because of their durability, versatility and aesthetic appeal. Epoxies have been used for years in applications such as crack repair, primers and top coats for floors. With an unlimited range of colours and even clear options available, epoxy coatings don’t just offer customisation but also act as the perfect bond layer for higher performance topcoats like polyurethane or polyaspartic materials. For thicker applications, 100% solids epoxy is often preferred for its fast curing time and impressive strength.

If you’re still not ready the big investment

We have another budget-friendly option for you

Ribbed Floor Tiles

No Gap Floor Tiles

Which one will you select?

Areas we serve

F.A.Q.

Frequently Asked Questions

There are various epoxy systems 100% solid epoxy, water-based, solvent-based and polyaspartic alternatives. Choose based on purpose (e.g. vehicle traffic, chemical exposure, shine preference) and get examples of past projects similar to your garage for reference.

Installation time varies depending on the floor size, level of prep needed, epoxy type and curing time. Plan for 1–2 days typically 1 day prep and coating, plus proper cure time before use.

When installed correctly, epoxy flooring is highly durable, resisting stains, chemicals, impact and wear. Its longevity depends heavily on surface preparation, coating thickness and maintenance routines.

Yes, but the surface must be properly prepared. Old concrete must be cleaned and mechanically ground. Tiled floors need leveling or removal before applying epoxy.

Use a soft broom, microfiber mop or mild detergent with water. Avoid acidic or abrasive cleaners. Regular cleaning preserves shine and prevents grit build-up.

Plain solid epoxy can become slick if wet. To improve traction, consider options like decorative flakes, aluminum oxide or silica additives in the top coat. These textures help reduce slipperiness.

Yes, once fully cured, epoxy is non-toxic and safe. Proper ventilation during application is important due to chemical fumes during the curing process.

Absolutely. Choose from solid colors, metallic swirls, flake finishes or even custom branding/logos for commercial applications.

Common causes include poor surface preparation, moisture in the slab, improper mixing or applying epoxy in high humidity. Hiring a professional avoids these issues.

Yes. Minor chips, cracks or surface wear can often be repaired by sanding the affected area and applying a fresh layer of epoxy or topcoat. For larger damage, professional refinishing may be required to restore a seamless look.

Usually, you can walk on it in 24 hours, but wait 72 hours before driving on it to ensure a fully cured and durable surface.

Standard epoxy is not ideal for outdoor use due to UV sensitivity. If outdoor coating is needed, use a polyaspartic or UV-stable topcoat.

Reach out to us

100% Customer satisfaction guaranteed